High by-pass ratio engines PD-14 and PW1400G-JM improve the fuel-burn, reduce the noise and emission levels For the first time fly-by-wire system of a passenger aircraft has been aggregated with active side-sticks with full feedback effect

THE MOST COMFORTABLE AIRCRAFT IN ITS CLASS

Extended fuselage diameter (4,06 м) provides: - enhanced passenger and crew comfort - 20—25% volume extension of the overhead bins 15–30% window size extention advantage compared to aircraft of its class.

More comfortable in-cabin air pressure (equals the pressure at the altitude of 1,830 m above the sea level versus 2,400 m inside any aircraft cabin of the same class).

COMPOSITE MATERIALS

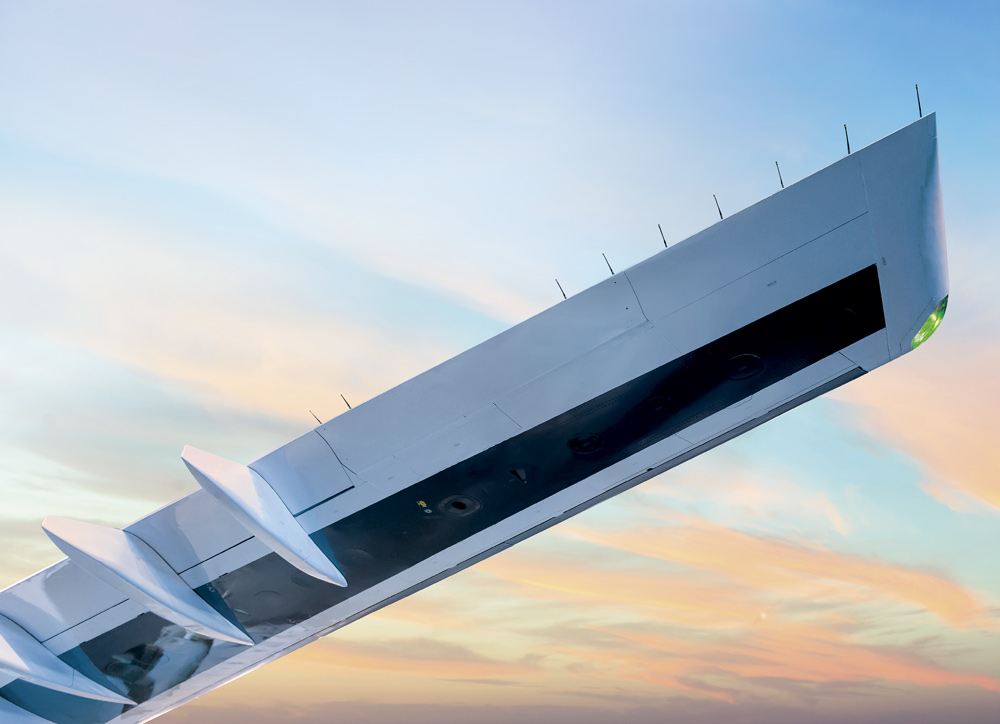

The use of rigid and lightweight composite materials allowed to design a wing of high aspect ratio and improve aircraft aerodynamics, that, along with new generation engines, has enabled to reduce fuel consumption. High aerodynamic

characteristics were achieved simultaneously with the fuselage diameter extension, which provided enhanced passenger comfort.

Russian analogues of imported materials have been developed with the participation of Moscow State University and Rosatom enterprises. The materials have been thoroughly tested within the framework of general qualifications

in laboratories certified by the Federal Air Transport Agency according to methods agreed with authorized certification centers.

The company “AeroComposit-Ulyanovsk” launched mass production of the wing caissons and center section using infusion technology. In July 2021, the Irkutsk Aviation Plant completed the installation of the first wing made of domestic composites on the MC-21-300 production aircraft.

MC-21-300 EQUIPPED WITH PW1400G-JM

Is being certified in accordance with both Russian and European standards. Working groups operate within the frame of the certification program, involving experts from the Federal Air Transport Agency and EASA. Currently 4 test MC-21-300 aircraft are engaged in flight certification tests.

INTERIM RESULTS OF FLIGHT CERTIFICATION TESTS

- flight performance characteristics were assessed

- takeoff and landing performance assessment is nearing completion

- flights were performed to determine the minimum lift-off speeds

- the efficiency of aircraft systems has been assessed

- stated characteristics for a cruising flight speed of 870 km/h and a maximum flight altitude of 12,200 m have been confirmed

- the possibility of safe movement on the runway covered with precipitation in a wide range of speeds with trouble-free operation of the cruise and auxiliary power units has been confirmed

- the tests of maximum calculated angles of attack and flutter in various configurations have been fulfilled

- the main engines’ and auxiliary power units’ in-flight starts have been performed

- the characteristics of the take-off and landing with simulation of the engine failure have been evaluated

- the efficiency of the instrumental landing system, as well as of the equipment for navigation, landing and external lighting has been confirmed during the night flight

- conducted flights under the noise assessment program on the ground

- the aircraft was tested in conditions of natural icing in Arkhangelsk

- special certification ground tests for indirect lightning impact and HIRF were carried out

The results of both — flight and ground tests- confirm correctness of main design. Flight tests are planned under the expected operating conditions, which will take place in various regions.

PRODUCTION

5 test aircraft and 2 aircraft for ground testing are manufactured IAP completes assembly of the first aircraft intended for the customers In the assembly shop of the plant, work is underway on the fuselage of the second aircraft.

Three more aircraft are at different stages of aggregate assembly. Manufacturing of parts for subsequent machines is underway. The first operator is the Aeroflot Group.

MC-21-310 EQUIPPED WITH PD-14

Equipped with the latest Russian UEC PD-14 engines. Fulfilled its maiden flight on the 15th of December 2020. On the 22nd of June 2021 it arrived from Irkutsk in Ulyanovsk to be painted. On the 7th of June 2021 the aircraft arrived

to Zhukovsky to flight tests.

DEVELOPMENT OF PRODUCTION FACILITIES

The Cooperation participants involved in MC-21 Program are extending their industrial potential in order to reach the set rates of mass production. New stations for automated assembly lines are being commissioned. Logistics center, airfield testing and customization buildings are commissioned in Irkutsk. Irkutsk Aviation Plant output shall stepwise achieve 72 aircraft per year.

CUSTOMER SERVICES

Aftersales system development is synchronized with MC-21-300/310 program development. It is planned to use aftersales system developed in the interests of the Superjet 100 program. System capabilities will be expanded to cover fleet growth and geography of deliveries.

DESIGN MEANS TO SUPPORT MAINTENANCE

Maintenance by technical status Increased resource of assemblies. Reducing the number of resource-constrained components. Efficient inflight system for integrated monitoring.

MOST ADVANCED TECHNICAL DOCUMENTATION

Basic technical documents package is developed and being updated according to aircraft testing results. Developed in user-friendly electronic format and complies with ASD S1000D standard. Reflects configuration of every and each

aircraft and enables customers to draw up own working procedures. Web-portal for access to «always actual» software and technical documentation is being developed.

TRAINING EQUIPMENT DEVELOPMENT

Training equipment is developed and being updated according to testing results:

- full flight simulator, level D

- flight procedures training device, level 2

- set of cabin emergency evacuation training devices

- computer based training complex

A set of training devices is placed in the training center of PJSC Aeroflot. Flight, cabin crews and maintenance personnel (including instructors level) training program approved by the Federal Air Transport Agency.

MATERIAL SUPPORT

The range of spare parts has been determined, taking into account the recommendations of suppliers and operating experience of similar products. An order has been drawn up for the production of spare parts for the advance stocking of warehouses.

Plans for expanding and retrofitting Sheremetyevo airport warehouse have been developed.

MAINTENANCE

Priority order has been ordered for ground handling facilities for equipping maintenance centers, both our own and partner ones. The technology for performing maintenance by the forces of operational engineers is being tested, including the expansion of the range and clarification of instructions for the use of ground support equipment.