The issue of ensuring the quality of aviation fuel and lubricants is a global problem nowadays.

In world practice, there are two systems for regulating aviation activities in the field of aviation fuel and lubricants. The flight safety system in civil aviation of the USSR worked for many years and proved its effectiveness. Today, Russia, having levelled the state control system in matters of aviation fuel supply, has not decided on its priorities and has not documented them.

From the end of the zero years, as a result of industry liberalisation, the reliable and effective system of access for aviation fuels and lubricants to civilian aviation existing in the USSR was practically destroyed. The current situation in the domestic aviation fuel supply is characterised by self-removal of the state from controlling the quality of the produced aviation fuel, which led to an imbalance of the system, the emergence of precedents for the detection of uncharacteristic substances and compounds in the fuel that carry operational risks for aircraft and high risks of flight accidents. At the same time, a change of priorities occurred: flight safety is sacrificed to commercial benefits.

Substandard fuel accounts for more than half of the investigated causes of flight equipment failures. One problem is that today the final product of production is not legally required to comply with airworthiness standards.

The lack of updating and mandatory application of the documentary base in relation to aviation fuel supply procedures, in addition to reducing the quality of the fuel itself, has led to dangerous precedents for the detection of substances such as polysiloxanes and mechanical impurities in the fuel. The definition of these components is not currently provided for in the Technical Regulations.

In order to get out of this situation, the country needs to decide on the strategic choice of a model for regulating airworthiness issues, including issues of confirming the quality of aviation fuel and lubricants by all process participants. In this case, the order of priorities must be returned: flight safety and, therefore, human life should be higher than the commercial component. The most important step in solving the problem under discussion may be the introduction of an “Electronic Fuel Passport”. The creation of such a passport as an element of digitalisation of the qualitative characteristics of oil and gas fuels will allow to avoid getting a poor-quality product into the aircraft fuel tank by almost 100%.

The algorithm for creating an "Electronic Passport"

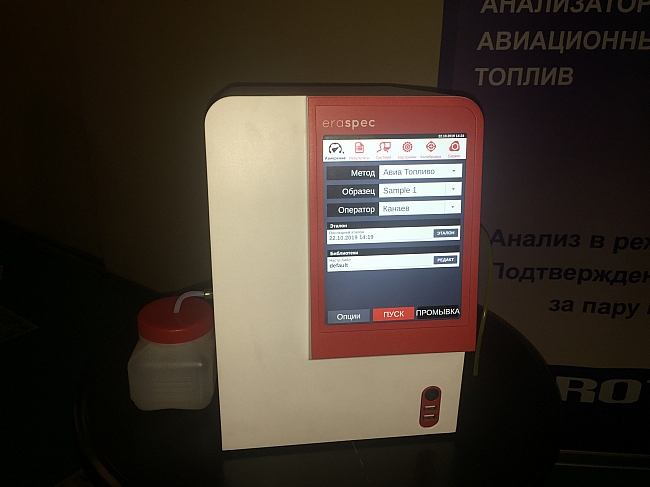

The companies manufacturing jet fuel include accredited laboratories that monitor products for compliance with the requirements of State All-Union standard 10227 and the Technical Regulations (TR). Products are sold in accordance with the passport, the data from which are assigned to the created spectrum of the fuel sample - this is the so-called “fingerprint” of fuel. Further along the chain, getting to the tank farm or immediately to the refuelling complex, the fuel passes the input control according to the TR. Using the portable portable device ERASPEC, it is possible to check the quality of incoming fuel in the literal sense of each volume by which it is transported for storage and transshipment. This is due to the quick analysis in operational or mobile conditions without the use of consumables in 2 minutes. In the case of substandard quality, the probability of the test fuel entering the petroleum base fuelling complex is zero.

In the process of storage and preparation for dispensing at a refuelling complex or fuel tank, fuel can not only be mixed with the same fuel, but also undergoes preparation in the form of adding various additives, after which the enterprise also issues a passport for goods in accordance with the TR. At this stage, a similar procedure for assigning fuel test results to a specific spectrum occurs. At the request of the user, it is possible to study the properties of additives and their subsequent identification as part of jet fuel.

There is no laboratory at the final point of refuelling the product in the aircraft’s fuel tank, that is, at the airport, but there is a device whose data library contains information on fuels produced at the refineries and upgraded at the petroleum base / fuelling complex.

The operator in online mode by pressing one button receives the result in a couple of minutes, according to which the device "recognises" or "does not recognise" the fuel, planned for refuelling in the tank. In the case of substandard quality, the probability of the test fuel getting into the aircraft fuel tank is zero. One of the reasons for the contamination of jet fuel is its transportation, which is precisely monitored by the device at all its stages.

Note that the refineries and petroleum base / fuelling complex contain qualified laboratory personnel, while field operation of the airport does not require this. The created database throughout the country, including manufacturers of fuels, petroleum products and refuelling complexes, will contain an infinite number of spectra of both conditioned and substandard fuels.

This is precisely what will allow the device to accurately answer the question: “yours is a stranger”.

ERASPEC - express analyser, Fourier spectrometer - reliable confirmation of the quality of the product throughout its entire life cycle, from the manufacturer to the refuelling in the wing. The device allows you to control the basic parameters of the fuel according to the requirements of the Technical Regulations, on the basis of the created Database of spectra of commercial fuels, tested in an accredited laboratory according to State All-Union standard 10227. The device implements a method of comparing the test and already known fuels on the basis of the "fingerprint" and its further identification, taking into account the coefficient reliability of the result.

At the same time, the qualifications of the personnel do not affect the reliability of the almost instantly obtained result in any way. Automatic sampling, its temperature control and the presence of an integrated densitometer for determining the density of commercial fuels according to ASTM D 4052 allow achieving the most plausible results. ERASPEC JET - a unique device on the market, which has no analogues, was created to work in the field and is successfully used in Russia and around the world. The algorithm for the formation and application of an electronic fuel passport is used in the practice of the Signal Scientific Center of the Federal Service for Technical and Export Control of Russia when implementing export control measures.

The implementation of this concept is seen as follows: Simultaneous equipping with devices of all refineries that produce jet fuel and petroleum base / fuelling complex, serving airports.

Further, as the spectrum library has been operating for several months, the airport ground services are equipped with instruments with access to the library data. The delivery time of equipment for equipping the entire structure of aviation and fuel supply is estimated from 6 to 9 months, the terms of the database - about 3 months. This is enough for the system to work in full. In other words, the system can be implemented within 12 calendar months for all airports of the Russian Federation with an estimated budget of about 1 billion rubles.

Implementation of the algorithm for the formation and use of the “Electronic Fuel Passport” will minimise the risk of flight accidents due to substandard jet fuel, and raise the flight safety system to a higher quality level. The effect of the implementation of the proposed concept will be as operational as the coordination of the issue of its implementation at all levels by the interested parties will be operational.

The concept of using an electronic passport in ON-LINE mode to confirm the origin of fuels and their quality indicators is already used by VINK. PJSC Gazprom Neft included this decision in the Neftekontrol program for the retail sale of ABenzine and DFuel. In order to fully restore order in this segment, organisations producing automotive fuel should equip their units with ERASPEC analysers. Also, they should be equipped at the same time with Rosstandart units, that is, FMC laboratories throughout Russia.

Today, more than 10 ERASPEC analysers are operated in the country in Lukoil divisions, 15 units. in Rosneft, more than 30 units. in Gazprom Neft, 3 units. in Tatneft, about 20 units. in Transneft and about 20 units. in other organisations. 50 laboratories manufactured and delivered by us, equipped with this device, are used by these companies to control the quality of petroleum products.

We hope that the proposed concept will be supported by a community of specialised specialists, approved by the heads of interested state and commercial structures, will find its application in the industry and will take its rightful place in the integrated flight safety system.

FAQ:

1. Question: How many ERASPEC devices will be needed to completely eliminate the possibility of substandard fuel getting into the fuel tank if 5-10 transhipments occur on the way from the refinery to the final consumer?

- At least 2 analysers are required - at the refinery and at the end user. However, if substandard fuel is detected at the place of use, the possibility of detecting a pollution point is difficult. In this regard, ideally, it is necessary to have analysers at each transshipment point.

2. Question: In the case of mixing fuel with additives or other additives (LIQUID-E, etc.), how will the fuel spectrum change? How will the device recognise fuel according to the “friend or foe” principle if the additive is introduced at an intermediate stage and its concentration does not exceed acceptable values?

- Additives are introduced in extremely small quantities, their detection by the IR method in such concentrations is impossible. In this regard, the spectrum of fuel with additives will be identical to the spectrum of fuel without them.

3. Question: What qualifications should process the spectra that enter the general database?

- There is no need for spectra to be processed by laboratory specialists; the analyser does this. Specialists only need to enter the fuel passport data when creating databases, if any. In this regard, some special qualifications for carrying out these procedures are not required.

4. Question: On which servers should the shared database be stored? Who will be involved in its organisation and maintenance?

- Databases are extremely small files that are created on the basis of tests of fuels with known parameters determined in accredited laboratories, primarily in the Central Laboratory of Refineries. They can be easily transferred over the network and from device to device using a USB stick. The host server itself can send new databases to all connected users. Special maintenance of the server itself is not required.

5. Question: How can a 0% counterfeit be guaranteed to a consumer if a human factor is present at each stage?

- To reduce the influence of the human factor, it is advisable to use ERASPEC analysers not only at production and end-user points, but also at intermediate points. Then hide the fuel change just does not work.

6. Question: Is it possible to develop express methods at the legislative level (test method, technical regulation) specially tailored for this device (and its analogues)?

- We are ready to take on the role of the developer of the National Standard “Petroleum products, motor gasoline, diesel fuel, aviation gasoline, aviation fuel. Express method for assigning an electronic passport to fuels and determining a wide range of fuel quality indicators using the near middle region of FTIR spectrometry and mathematical analysis ”

7. Question: How can I calibrate viscosity, acceleration parameters, flash point and other properties that are not directly determined from the spectrum?

- Properties, such as viscosity, acceleration parameters, flash point, are calculated from the databases used. If customer samples are poorly presented in the factory database, it is important to expand the database by adding typical customer samples. Only parameters determined directly from the spectrum are calibrated. This calibration is carried out at the factory and is confirmed during the verification of equipment.

8. Question: Can samples be added to factory databases?

- Yes, but we recommend also creating new databases based on the fuels used by the customer. The analyser allows you to store and use an infinite number of databases. The user himself determines which of the existing databases he will work with. All active databases will be considered as a large single database.

9. Question: How many samples do I need for the database?

- If the database should be used separately, it needs at least 40 samples for gasoline and 30 samples for measuring jet fuel and diesel fuel. Additional samples may be required for stable measurements depending on the range of samples.

10. Question: If I do not have 40 samples?

- Even a few samples (5+) will improve accuracy when used with factory libraries. Databases can be updated at any time in the presence of fuels with passports.

11. Question: Can I add the same result several times to the database?

- It does not make sense. If a spectrum of such fuel already exists in the library, the device will show this in the results menu.

12. Question: Do I need to measure samples for the database on all devices that are in the way of fuel from the refinery to the consumer?

- Not. Databases, first of all, should be created at refineries and then transferred to all analysers that are in the way of fuel movement. This will allow you to control the fuel at each stage of transportation.

13. Question: Is it possible to detect a new substance using ERASPEC?

- ERASPEC will issue a warning on the results screen if an unknown substance is detected. The device uses more than 50 spectra of pure substances to calculate the composition of gasoline. This includes a wide range of conditioning and substandard substances that affect fuel quality. Additional substances can be added to the analyser software after tests at the manufacturer, if it is possible to determine them by IR spectrometry.